Industries We Serve

Tools

Plastic injection moulding

Forging

Sheet metal forming

Metal die casting

Accuglobal solutions for mould and die making

The future at its best.

Fast changes of models, constant new requirements for the look and feel of components, more wear-resistant materials, ever-shorter changeover and delivery times… the mould and die making industry is facing major challenges. Whether you're machining moulds for abrasive fibre glass materials, hard steels or special geometries: Shape the future with tools from Walter.

Milling cutters

Indexable insert milling cutters are cost-effective and flexible; solid carbide milling cutters are the top choice for small diameters.

Threading tools

Whether mounting threads or connecting threads (e.g. for cooling), pressure resistance and tightness must be ensured.

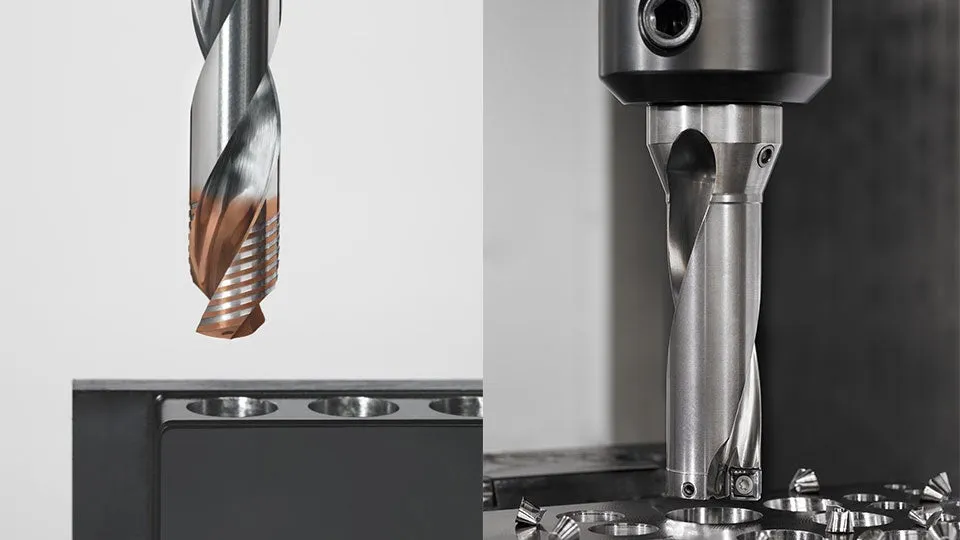

Drills

To be able to make coolant channels, for example, close to the workpiece surface in such a way that saves energy, drills have to be stable against displacement.

Product data

Walter's unique database makes it possible to test and optimise your processes in advance – during the simulation